The Challenge

Fugro required rapid mobilisation support for an offshore project departing from Dampier. The scope involved urgent structural modifications and certified hot works on key vessel equipment to meet strict operational deadlines and marine safety requirements. Time constraints, offshore safety compliance, and limited dockside access added complexity to the task.

Our Approach

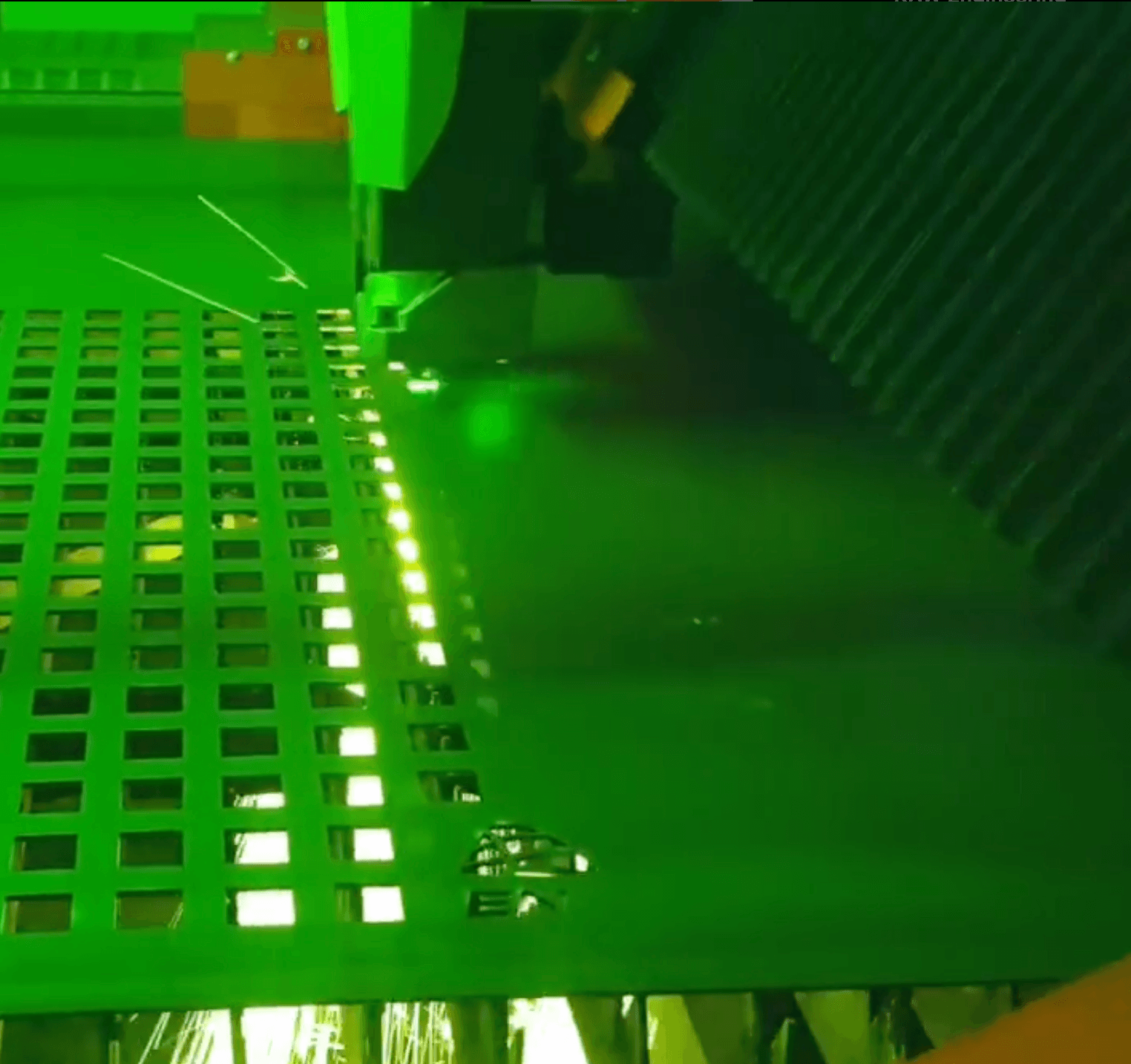

KAW Engineering deployed an experienced fabrication and marine support team to Dampier, coordinating closely with Fugro’s project engineers. All hot works were performed under stringent safety controls, including confined-space protocols and Class-approved welding procedures.

Custom steel supports, access platforms, and bracket reinforcements were fabricated and installed on-site, with QA documentation and NDT testing completed prior to vessel clearance.

The Impact

The vessel was mobilised on schedule with no delays to Fugro’s offshore campaign. The structural modifications enhanced equipment reliability and operational safety during the project’s duration.

Project Capabilities